Cement Kiln

-

A horizontal pipe, normally laid down on two resting stations, is typical for cement kilns.

Traditional resting stations consist of ball races that spin in roller stations. For rotating pipes that are very long, even more resting stations are used, in order to prevent the pipe from sagging.

With the help of large ball bearings, short rotating pipes can be operated with even one resting station, since these bearings have high stiffness.

Rotating pipes can be furnished with fixtures, depending upon their purpose:

• Lifting shovels to mix the product more thoroughly

• Heating pipes that are brought to the desired temperature with water, steam, heating gas or thermo oil.

• Cooling pipes that take off heat with water or cooling air

• Internal brick lining, that protects the (metallic) shell from overheating

The rotating pipes normally consist of

• Mild steel for temperatures up to 350°C (660°F)

• High-quality steel for temperatures up to 550°C (1000°F) and corrosive products

• High-temperature steel for temperatures up to 950°C (1750°F)

• Ceramics for temperatures up to 1400°C (2550°F)

Get the Flash Player to see this player.

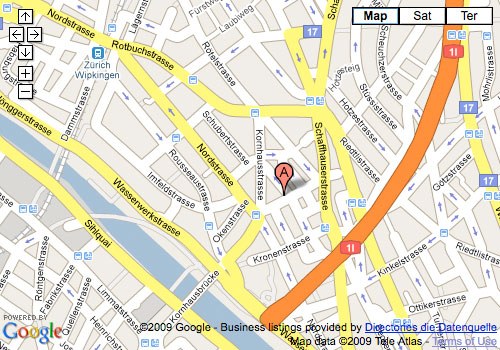

see large map